The Many Forms of a Flight-Qualified Antenna

June 2020

In a previous post, we mentioned some of the environmental testing standards that JEM Engineering follows in order to classify and qualify our antennas. In this post, we explore what makes a “flight-qualified” antenna, as well as the many forms it can take.

In order for an antenna to be qualified for mounting onto a non-stationary ground plane, it has to meet stricter vibration testing standards than it would for stationary mounting. Additionally, atmospheric factors have to be considered. A stationary antenna, if mounted outdoors, will also have to withstand harsher temperatures and weather conditions, and therefore pass more rigorous temperature, wind, dust, humidity, and corrosion tests, to name a few.

Naturally, a vehicular antenna, especially one mounted onto the exterior of the vehicle, will need to withstand the aforementioned non-climate controlled conditions, in addition to increased shock and vibration. A flight-qualified antenna, however, has to meet even higher standards than a vehicular antenna. Additionally, it has to operate well in high altitudes.

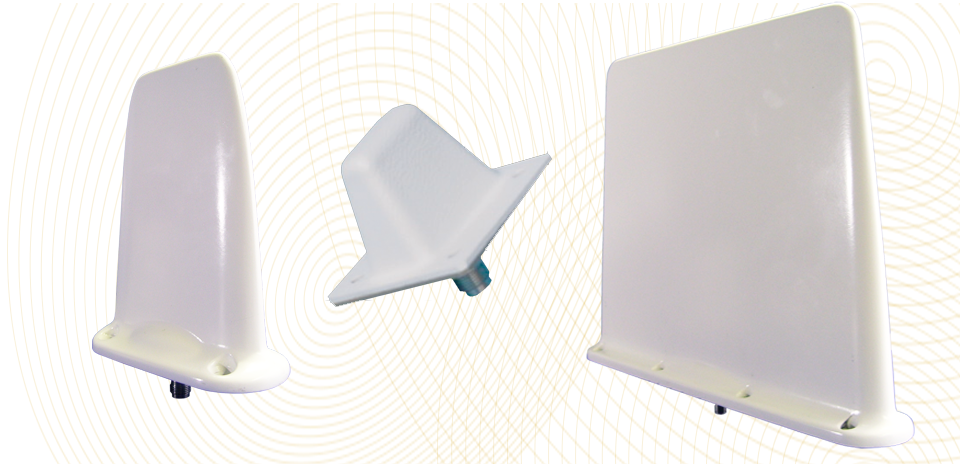

A flight-qualified antenna can come in many different forms.

We are proud to offer a variety of flight-qualified antennas, ranging from flat panel, to box-type, to blades, and even flexible peel-and-stick antennas. These antennas are suitable for a various applications, including multi-band communications, EW, ISR, SIGINT, as well as satellite communications.

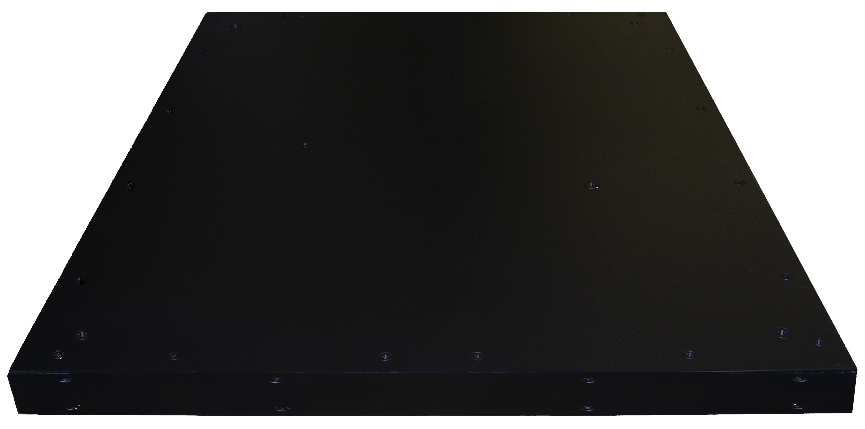

Among our many box-style antennas is the JEM-238MFC, which comes in an ultra-low-profile form factor designed for 1.2″ (3.18 cm) cavity depth.

It is one of our Magnetic Flux Channel (MFC) antennas, which means it does not utilize electric charge to achieve propagation. That being said, it be placed directly on, or even within, conducting structure with no ill-effects on radiation or impedance match performance.

All measuring less than 9″ (22.6 cm) long, and weighing 1lb (0.45kg) and under, our box-type wideband sector antennas (WSAs) are portable and multi-functional. They feature 90-degree angle brackets, which allow for easy mounting and dismounting.

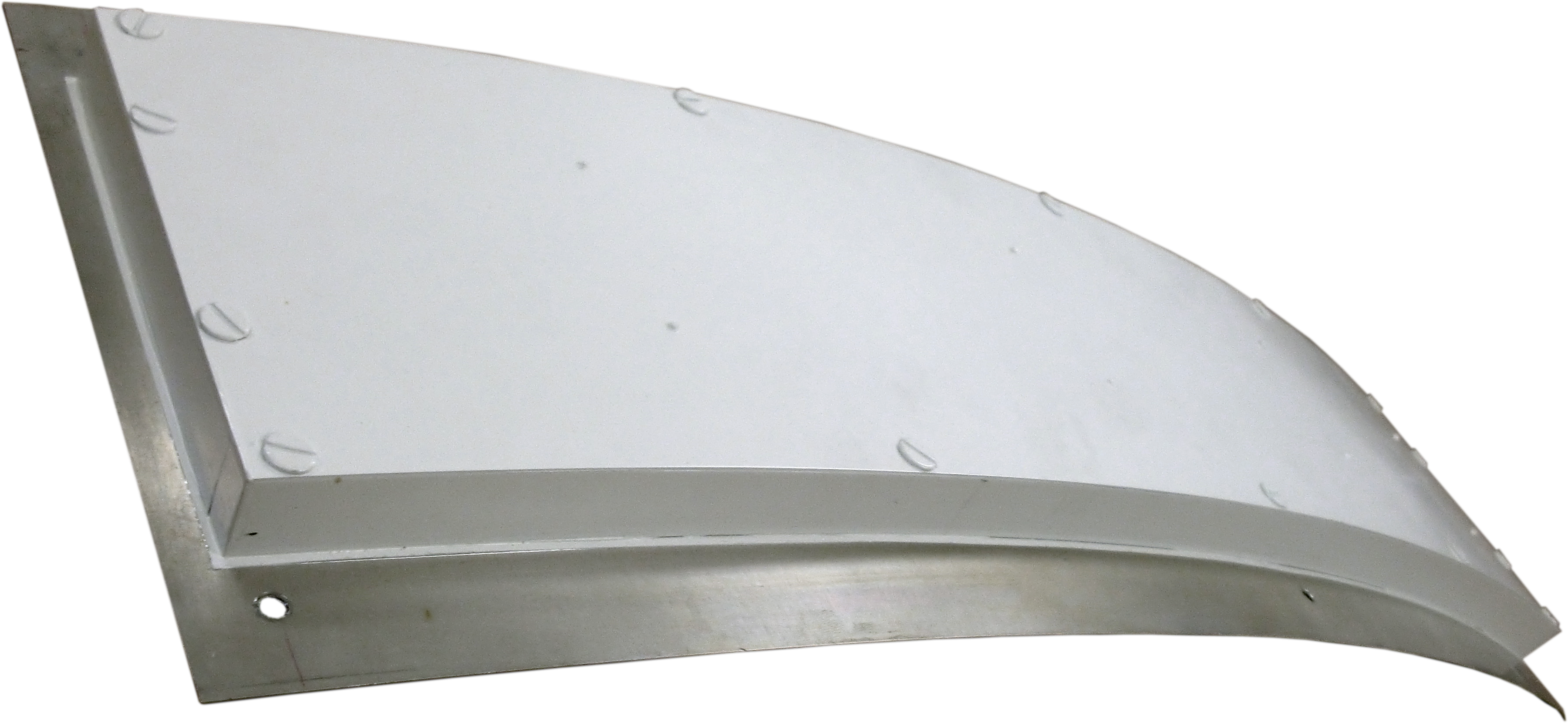

Specifically designed for aerodynamics, blade antennas are often mounted to the exterior surface of an aircraft. Ranging in size and frequency band, our UVW products used for ground-to-ground, air-to-ground, and ground-to-air communication systems. They are also optimal for unmanned aerial vehicle (UAV) communications. The UVW-0430A is suitable for sensor systems and low drag operations.

In addition to readily available antenna products, JEM Engineering offers custom antenna development. We often create special antenna designs to meet our customers’ unique requirements. Our blog post, The Makings of a Reliable Antenna, briefly explains some of our development processes.

Latest Posts

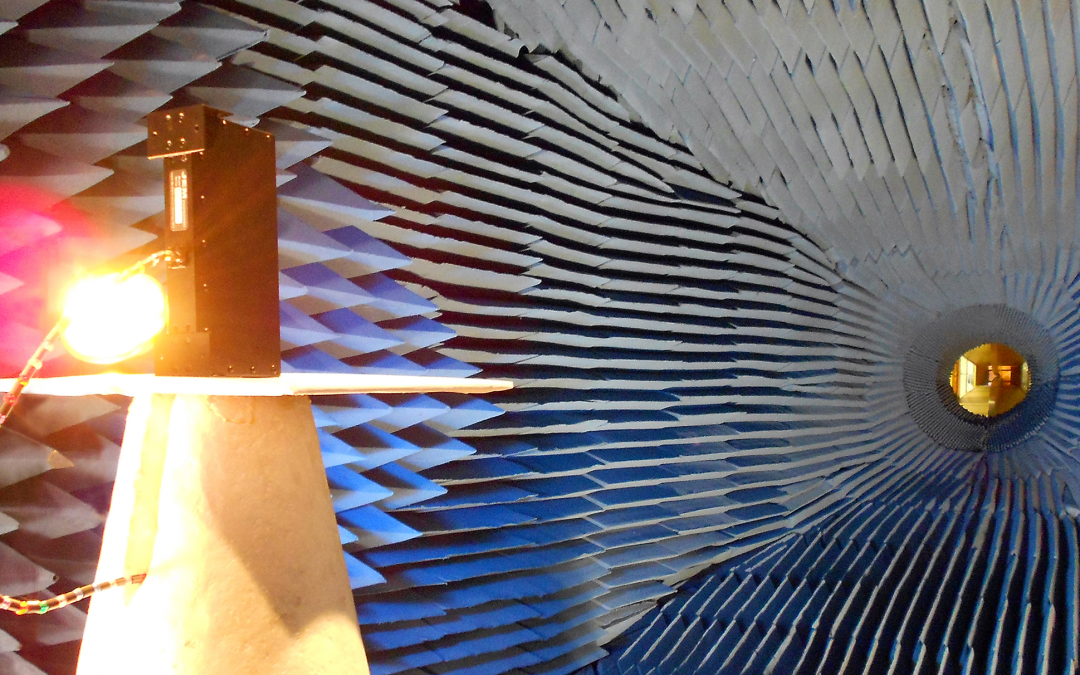

Which Testing Chamber? TATF vs. SNF

JEM Engineering boasts two antenna testing chambers at our facility in Laurel, MD, within easy reach of both Baltimore and Washington DC.

STEM with JEM

Did you know that National STEM Day falls on the 8th of November each year? That’s because the abbreviation “NOV8” actually stands for “INNOVATE.”

Reshaping Antenna Design with 3D Printing

As we discussed in a previous post, before we can manufacture, we must prototype. For this step in the process, we are beginning to explore additive manufacturing, or as it’s more commonly known, 3D printing.

An Overview of Unmanned Aerial Vehicles — and their Antennas

An unmanned aerial vehicle, or UAV, refer to a vehicle that is able to fly remotely, either with some sort of controller or autonomously. An unmanned aircraft system, or UAS, includes not only the UAV, itself but also the person on the ground controlling the flight, as well as the system in place that connects the two of them.