Radiofrequency Test Fixtures

November 2020

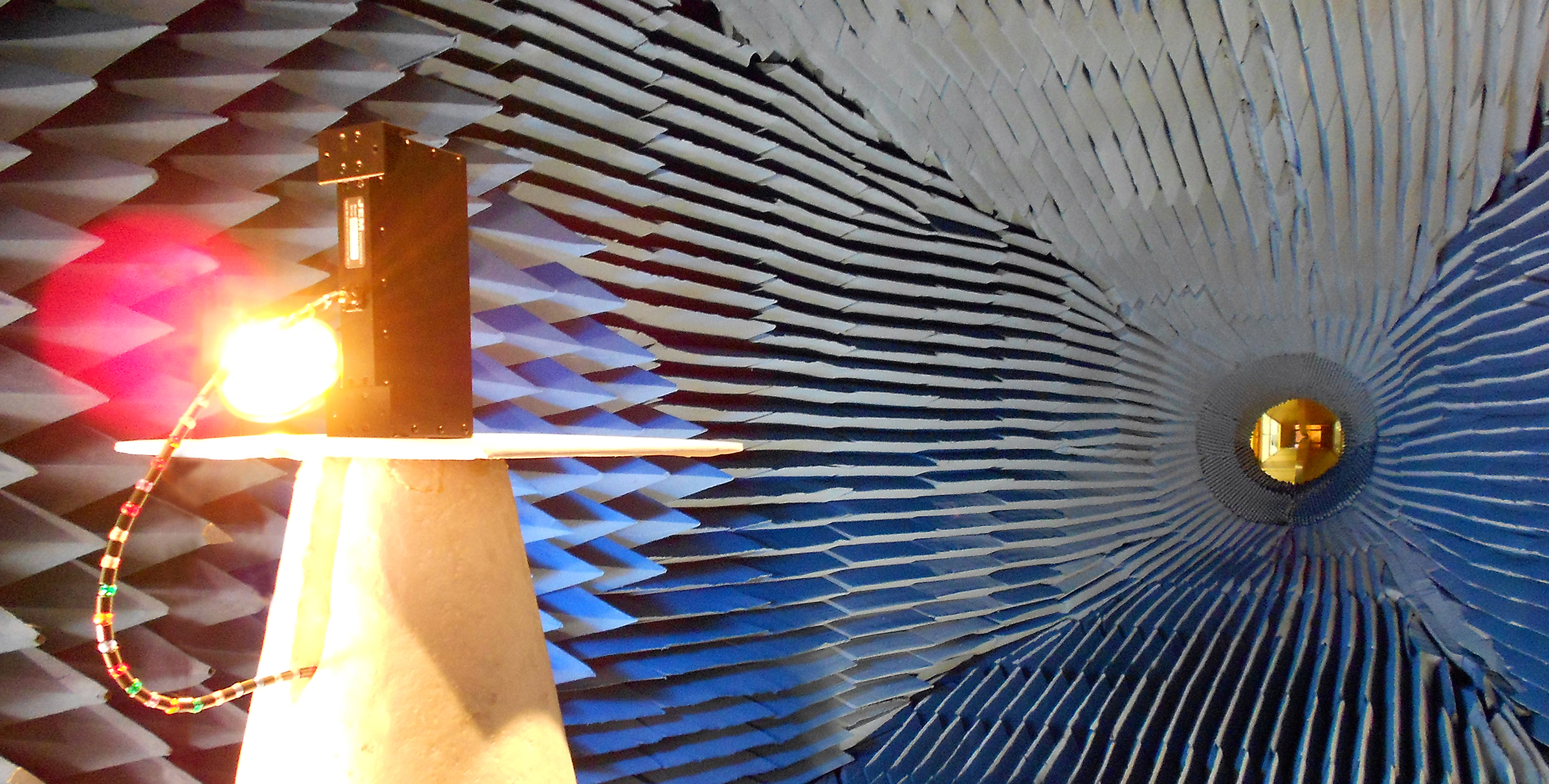

JEM Engineering offers both on-site and remote RF testing services at our facility in Laurel, Maryland. Our Spherical Near-Field Chamber (SNF) and Tapered Antenna Testing Facility (TATF) can measure a number of antenna performance factors.

While many tests do not require the use of a test fixture, tests that involve full 3-dimensional measurements in our TATF chamber will require some type of interfacing with our roll arm.

What materials are used for RF test fixtures?

Dielectric (non-conductive) materials, such as foam and wood, for example, are ideal for test fixturing. Such materials can support antennas and radomes without affecting their RF performance characteristics during a test.

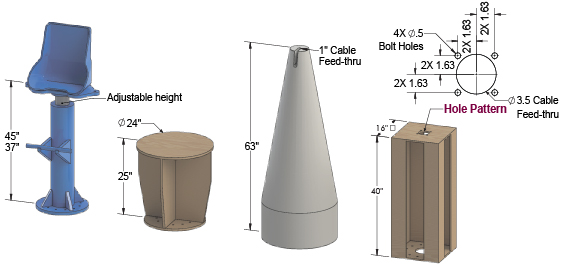

Does JEM Engineering provide its own test fixtures?

We house a variety of simple test fixtures, which we use to test our own antennas, as well as our customers’. Our existing structures allow us to fixture multiple antennas during the allotted test time.

Customers may also provide their own test fixture(s).

What about custom fixtures? If the weight of the antenna under test is off-center by more than 36”, or if the antenna requires a more specific configuration, a custom fixture may be necessary.

We have the in-house capability to build custom fixtures. While customers are encouraged to provide their own fixturing specifications (for example, with drawings and dimensions), we are generally able to fabricate the appropriate fixtures based on a unit’s design and specific test requirements.

Latest Posts

Advancements in Aerospace Antenna Design

With the latest advancements brought upon by more research and development, aerospace antenna design has continued to steer away from traditional manufacturing materials and methods.

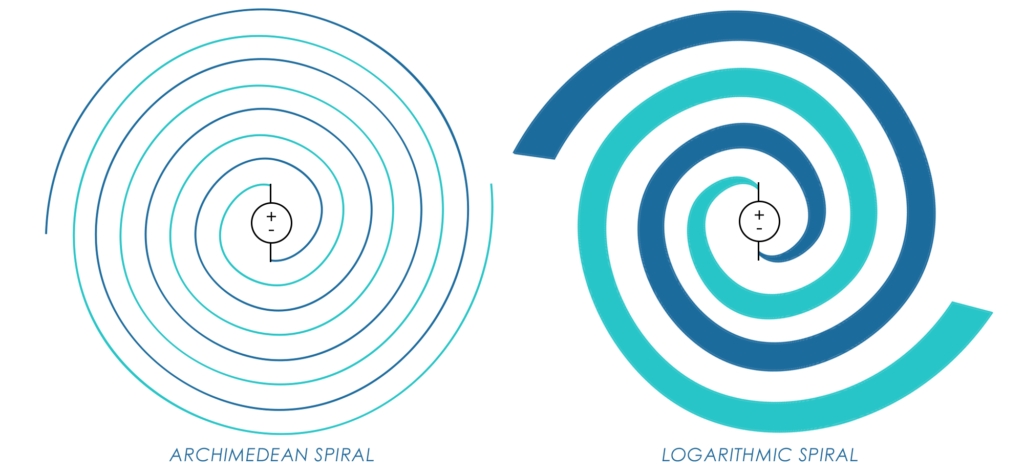

Large Bandwidths in Small Packages: Spiral Antennas

Spiral antennas are a type of frequency independent antenna first introduced in the 1950s. Their spiral design allows them to be relatively small.