Advancements in Aerospace Antenna Design

January 2021

With the latest advancements brought upon by more research and development, aerospace antenna design has continued to steer away from traditional manufacturing materials and methods.

According to an article featured by Military & Aerospace Electronics, the three main goals for selecting technologies for aerospace and defense are 1) ruggedness, 2) low-loss, and 3) cost-effectiveness.

Naturally, all flight-qualified antennas need to be rugged enough to withstand mechanical shock, vibration, and atmospheric factors. Also, it is generally important for any antenna to transmit and receive radio waves with as little energy loss (return loss) as possible. Higher loss may cause the antenna to overheat and can degrade its sensitivity.

Creating specialized aerospace antennas, especially those used for military and defense, must be a streamlined and repeatable process. Whenever mass production is involved, it is imperative to keep manufacturing costs as low as possible. While machined aluminum and hand-built thermoset radomes have made for very reliable antennas, fabricating such components often involve multiple steps—more labor and more machining means more cost.

Composite Substrates

Aside from yielding higher costs, another drawback of machined aluminum chassis is the added weight. Composite materials, on the other hand, are not only comparatively lighter, but also come in injection-moldable forms that allow for intricate design with higher repeatability.

Composite substrates can also be tailored to specific applications by using a variety of fillers, which have their own dielectric properties. These fillers range from carbon and glass fibers to foaming agents. Conductive-fiber fillers can absorb energy radiated in unwanted directions, increasing antenna gain by decreasing interference.

Most of JEM Engineering’s line of flight-qualified antennas are designed with carefully selected composite substrates, making them effective, rugged, yet extremely lightweight.

Conductive Coatings

Conductive coatings metallize materials such as plastics, chemically resistant composites, glass, and ceramics, in order to create conformal antennas on nearly any shape at minimal cost. High-quality conductive coatings meet flight-qualification standards.

3D Printing

In another post, we described how additive manufacturing is used in prototyping antennas. Mainly, it allows for reduced material waste, lower manufacturing costs, faster turnaround, and more design complexity.

Magnetic Flux Channel Technology

Developed by JEM Engineering, MFC antennas do not utilize electric charge to achieve radiation. Instead, the magnetic flux that resides in the MFC core shapes and supports an efficient form of magnetic polarization current in a specially designed flux channel. Unlike conventional antennas, the MFC may be placed directly on, or even within, conducting structure with no ill-effects on radiation or impedance match performance. For communications in the VHF/UHF bands (30 MHz to 3 GHz) MFC antennas can provide equivalent performance to conventional.

To learn more, read our blog post on our proprietary MFC technology.

Latest Posts

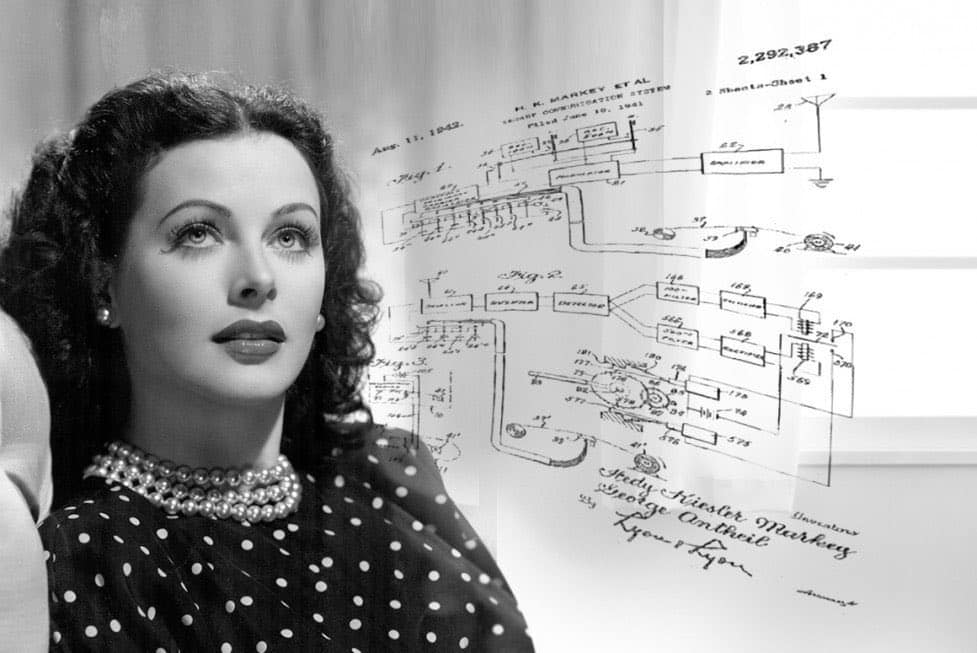

Hedy Lamarr: The Hollywood Actress Who Changed Wireless Technology

This Women’s History Month, we wanted to highlight the life and career of Hedy Lamarr, a famous Hollywood star whose lesser-known achievements include essentially laying the foundations for the spectrum-hopping technology we know today as WiFi.

Living Legends: James West and Jesse Russell

Every February, JEM Engineering honors the the African American Engineers who have made lasting contributions in STEM. This year, we’re excited to spotlight two living legends: James Edward West and Jesse Eugene Russell.

11 Ways the Antenna Industry Has Changed

In this issue, we wanted to reflect upon how the antenna industry has evolved over the past several decades.

Part II: Inspecting & Testing Antennas with UAVs

In this issue, we focus on how UAVs are used for inspecting and testing antennas. Perhaps an antenna is situated in a less-accessible area.