The Makings of a Reliable Antenna

October 2017Every product, specialty or off-the-shelf, must be designed, tested, and perfected by a team of experts, so that the end-user can be assured of its reliability.

The same applies to antenna design.

Our customers trust us to provide them with custom products, many of which have never been made in the past –or even conceptualized.

In this post, we share some of our antenna designing know-how…

1. Knowing where to start. Every single one of our antennas started out as a concept. Either a client or one of our own engineers wanted a device that could deliver a specific result, and our team worked to bring that concept to full-scale production.

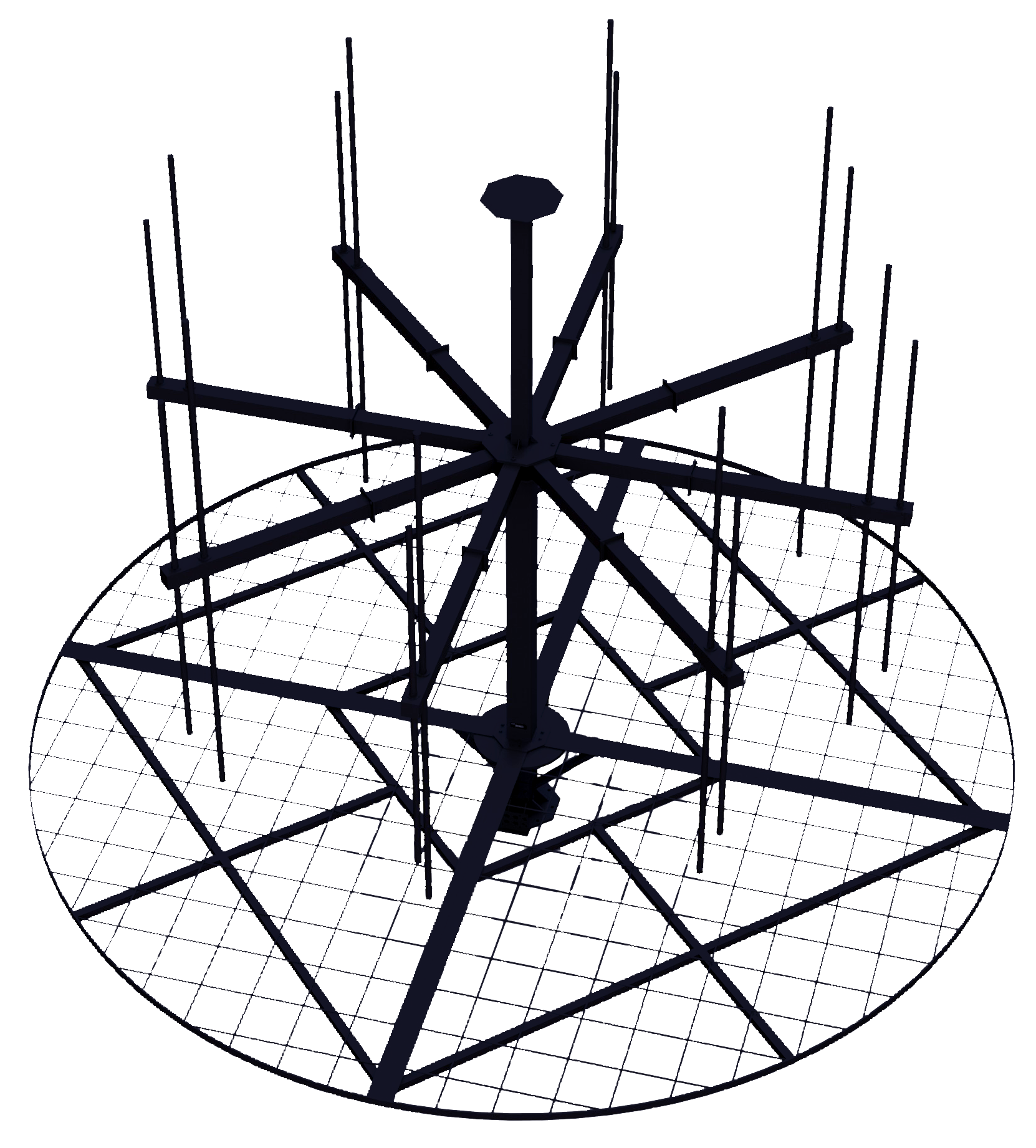

Our experts find out what the client is looking for, and quickly figure out how to make it happen. Our engineers have several decades of combined experience creating detailed drawings from 2-dimensional drafts to 3-dimensional CAD models.

2. Performing a structural analysis. Naturally, one would want to make sure that the antenna design doesn’t just look good on paper, but it also holds together, at the very least. However, it would be preferable to detect design flaws before spending money on building materials. For instance, COSMOS Static Analysis is an cost-effective way to perform a structural analysis on a computer-generated model, such as a SolidModel. We use this method to assess the feasibility of custom antenna design projects.

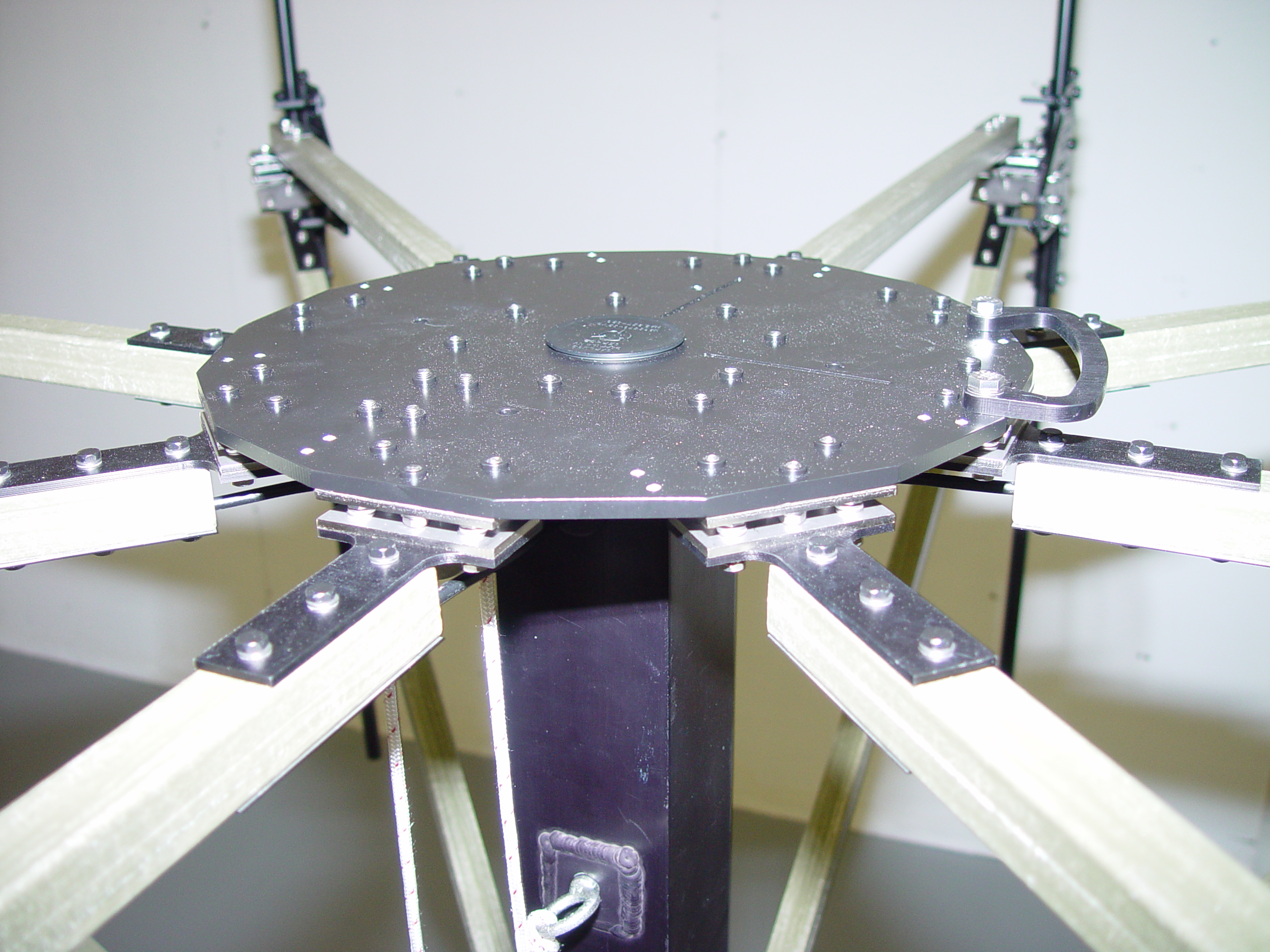

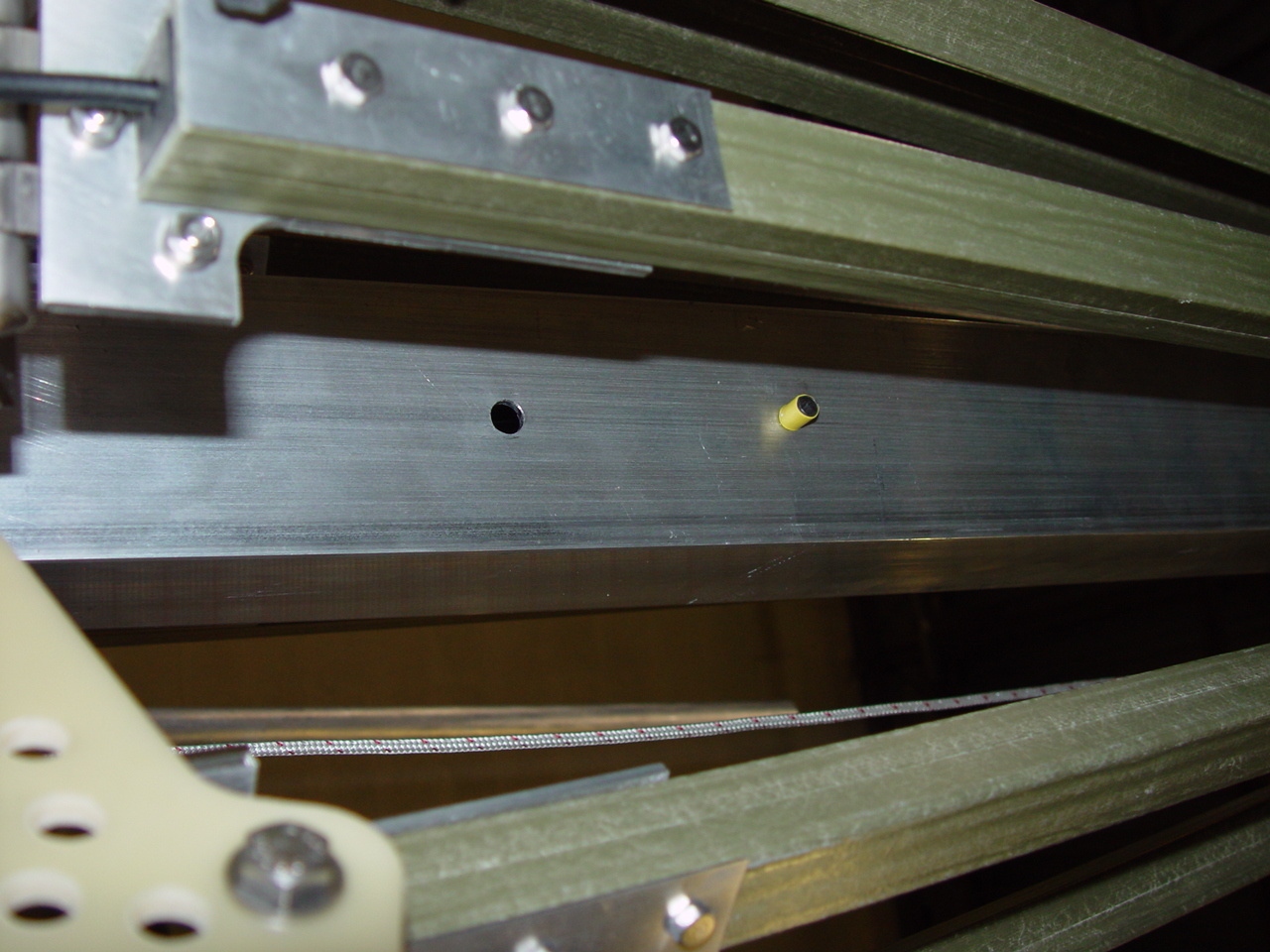

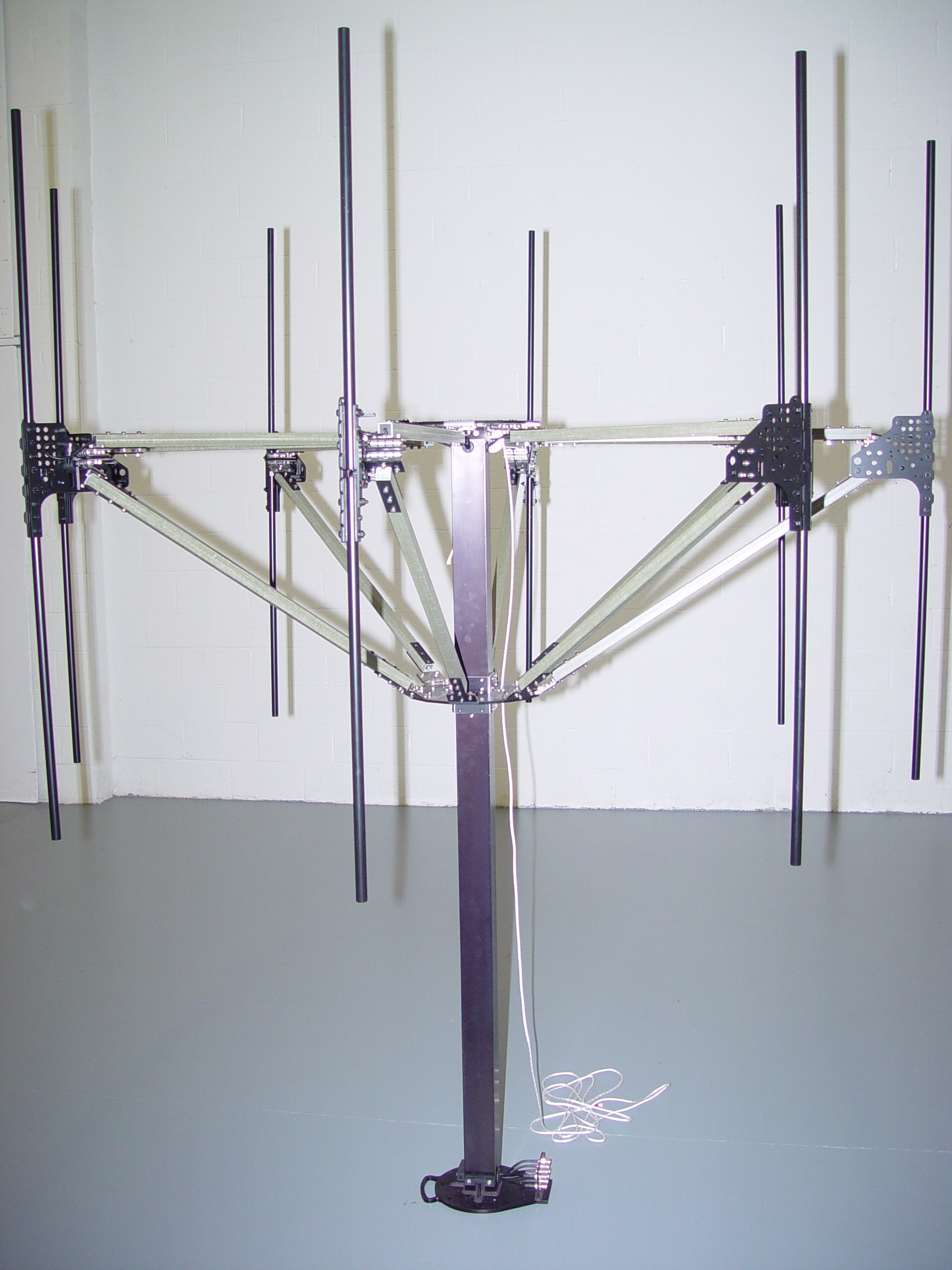

3. Developing a prototype. Before one builds the final product, they must create a prototype to not only further evaluate a design, but to also establish the most efficient assembly methods for it, and assess the cost effectiveness of its bill of materials. This also leads us to the next item on the list…

4. Using the right materials. The difference between selecting one material over another can not only mean cost savings, but also overall better performance and longevity. Our mechanical engineers excel at finding the best materials for a project, measurably increasing the practicality of a product.

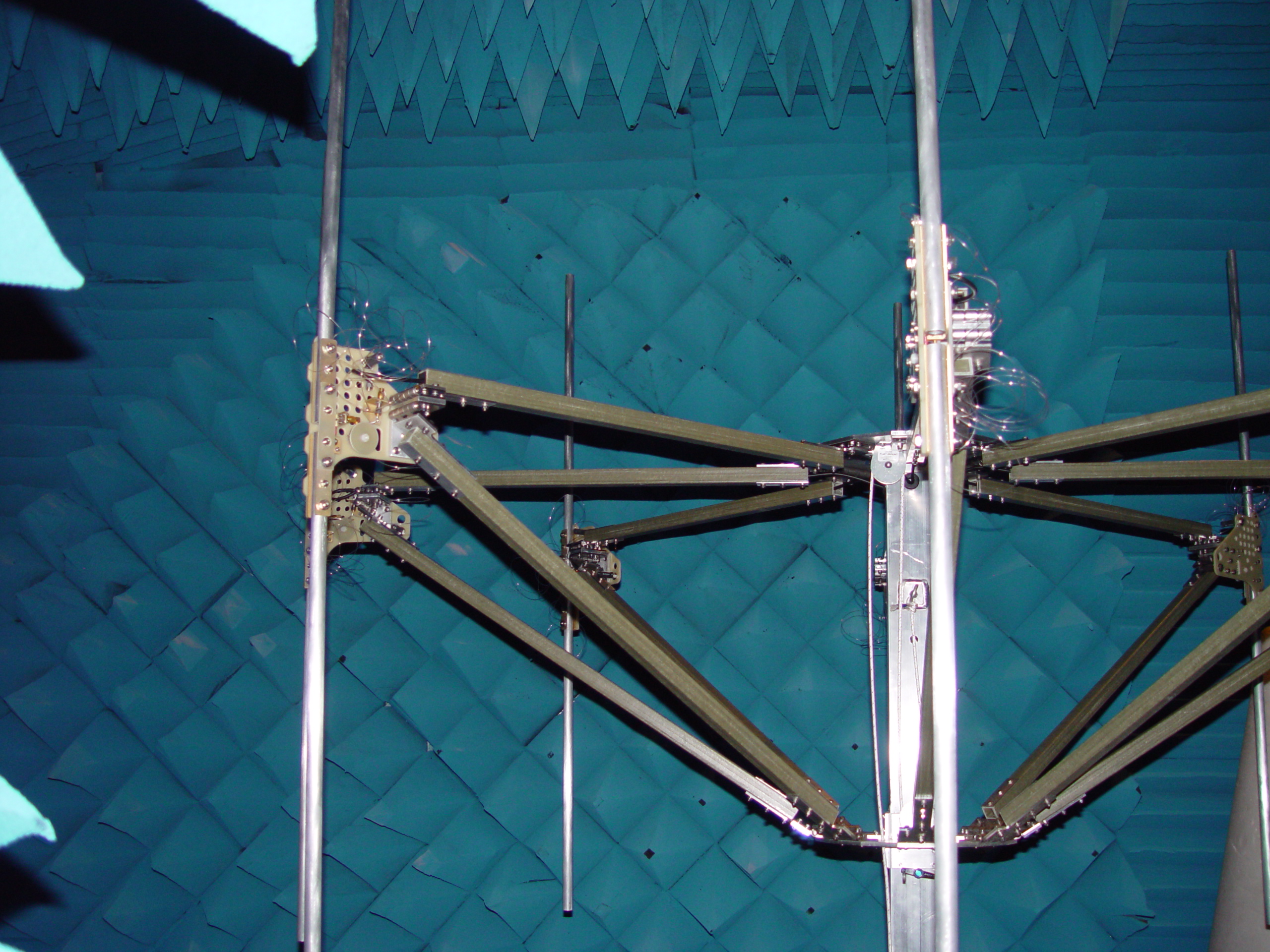

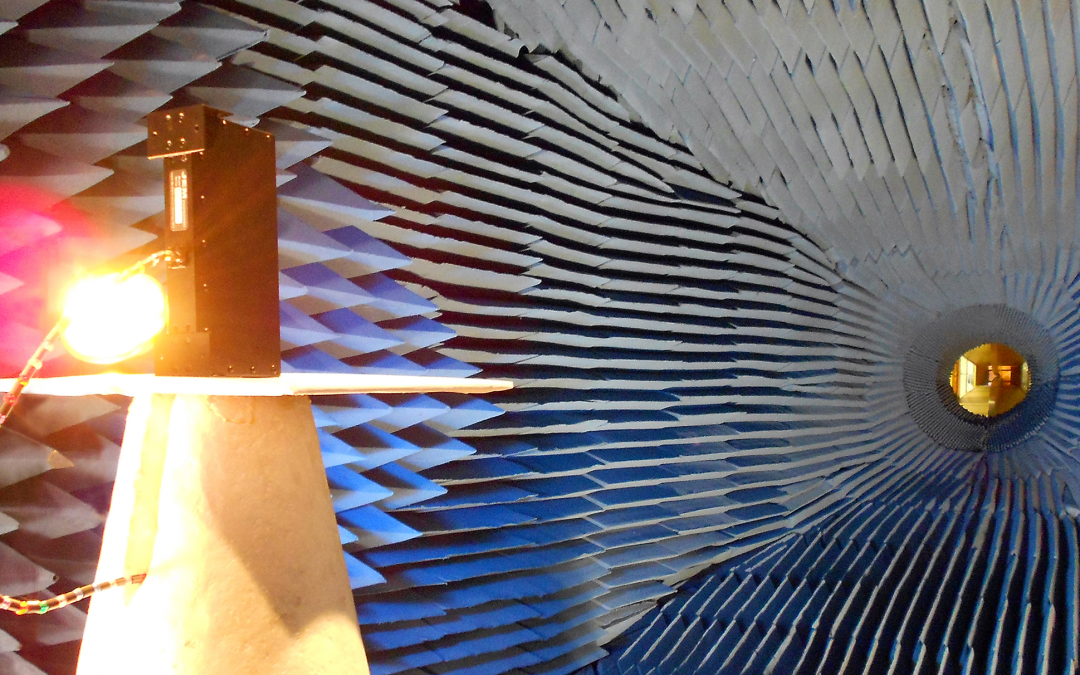

5. Seeing the prototype in action. So now it’s time to test the prototype. Before the product can go out into the field, it has to perform well in the lab. In our case, the antenna has to be carefully tested in one of our two test chambers by a well-trained and highly-skilled technician, who will provide guidance and support during the test, as well as assist with data analysis and interpretation. In a previous post, we explore antenna qualification in more detail.

6. Thinking about the whole package. After it is determined that the product works, the next point of consideration is its durability. Apart from material selection (see No. 4), the mechanical engineer designs the product’s housing and internal components so that as a unit it can resist various environmental conditions.

To make sure that the final product will survive, it must be put through rigorous environmental testing, including shock, vibration, heat, moisture, chemicals, wind, and frost. This is especially important for devices used primarily outdoors and/or mounted on moving objects.

Our external testing partners have these specific testing capabilities, which become available to our clients through us. Additionally, we can perform engineering analyses for electronics packaging to ensure that the encased antenna and its components are stored correctly.

In summary, designing a functional and structurally sound antenna has many crucial and complicated processes. Luckily, we can help you every step of the way! JEM Engineering staffs a Mechanical Engineering department capable of providing expertise to every antenna design. Send us an inquiry or call us at 301.317.1070 x. 113 to let us know what you need!

Quality & Customer Service – Our Policy

JEM Engineering exceeds customer expectations by providing custom antenna design, manufacturing and testing solutions with a commitment to comply with customer requirements and continually improve the effectiveness of the quality management system by maintaining a motivated, highly skilled and innovative team, and becoming a leader in our industry. Our commitment to quality is evident as our Quality Management System (QMS) is ISO 9001 Certified.

Latest Posts

Advancements in Aerospace Antenna Design

With the latest advancements brought upon by more research and development, aerospace antenna design has continued to steer away from traditional manufacturing materials and methods.

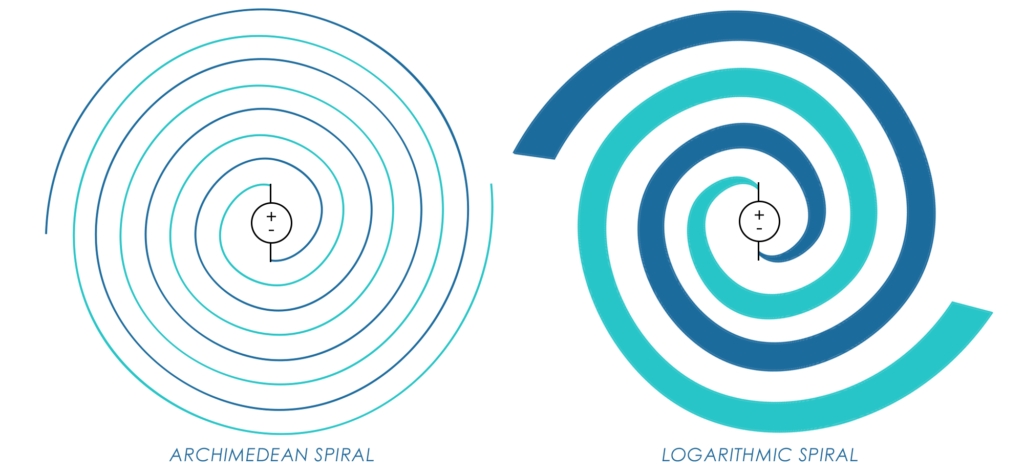

Large Bandwidths in Small Packages: Spiral Antennas

Spiral antennas are a type of frequency independent antenna first introduced in the 1950s. Their spiral design allows them to be relatively small.

Radiofrequency Test Fixtures

Dielectric (non-conductive) materials, such as foam and wood, for example, are ideal for test fixturing.

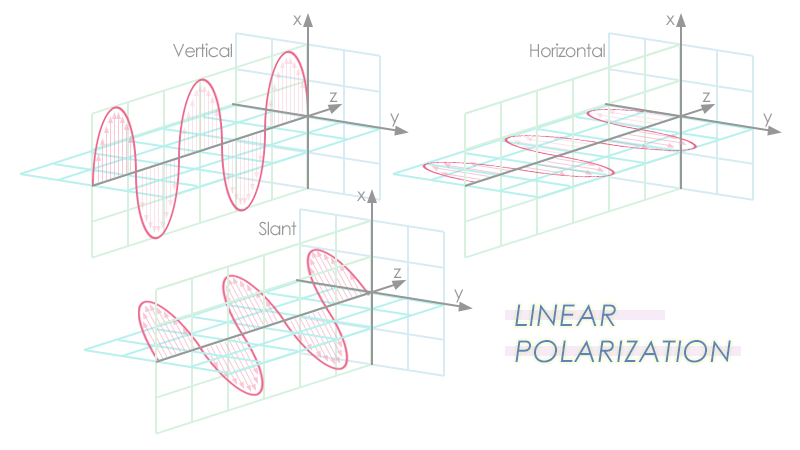

Intro to Antenna Polarization

The polarization of an antenna is loosely defined as the direction of the electromagnetic fields produced by the antenna as energy radiates away from it.

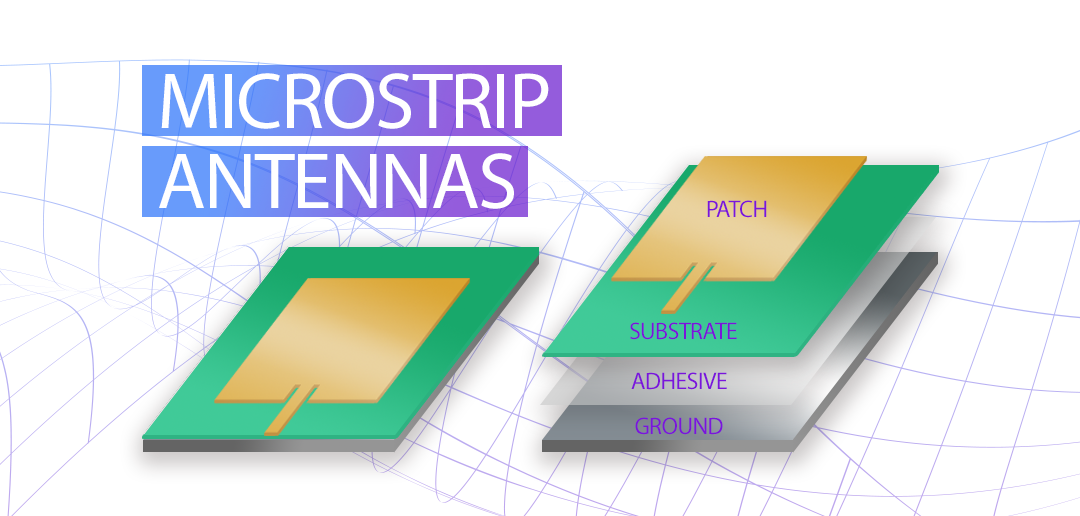

Microstrip Antennas: The Basics

Microstrip antennas were patented in 1955, although their origins trace back to 1953. They became more commonplace in the 1970s.